wheelchair lightweight transport

Lightweight Transport Wheelchairs: Engineering Innovation Unleashing Travel Freedom

Lightweight transport wheelchairs represent the crystallization of modern rehabilitation engineering and materials science. They perfectly unify the traditional contradictions of "portability" and "functionality," providing wheelchair users with unprecedented travel freedom. From ultra-light daily mobility aids to being easily folded into car trunks, these products are redefining the boundaries of what mobility assistive devices can achieve.

Core Value: Why Lightweight Matters?

Reality Revealed by Data

A typical manual wheelchair weighs between 35–50 lbs (16–23 kg), while a lightweight transport wheelchair can be reduced to 15–25 lbs (7–11 kg). wheelchair lightweight transport This seemingly simple numerical difference translates to tangible benefits in practical use:

Over 60% reduction in handling difficulty for female or elderly caregivers

Lower car fuel consumption due to reduced load (significant over long-term use)

Drastically decreased risk of overweight luggage during air travel

30–40% reduction in pushing force required for daily operation

Multi-Dimensional Improvement in Quality of Life

The impact of lightweight design extends far beyond physical weight. Studies show that users of lightweight transport wheelchairs:

Experience a 45% increase in social activity participation rates

See a significant rise in confidence and frequency of independent travel

Have lower caregiver relationship stress indices

Show a 2.3x increase in willingness to use public transportation

Materials Revolution: The Technical Cornerstone of Lightweight Design

Civilian Application of Aerospace Materials

Material innovation is at the core of modern lightweight wheelchairs:

Titanium alloy frames: Offer twice the strength-to-weight ratio of steel and excellent corrosion resistance, but at a higher cost

Aviation-grade aluminum: 7000-series aluminum alloys strike the optimal balance—20% lighter and 30% stronger than ordinary aluminum

Carbon fiber composites: The top-tier choice, 40% lighter than aluminum but expensive and complex to repair

High-performance polymers: Nylon composites are used for non-load-bearing components to further reduce weight

Structural Engineering Optimization

Using modern design tools like finite element analysis, engineers can:

Eliminate redundant materials to achieve "just enough" structural strength

Optimize tube diameter and wall thickness, reinforcing critical stress points

Design hollow or honeycomb-structured components to reduce weight while maintaining rigidity

Creatively adopt triangular support structures to maximize the stability-to-weight ratio

Type Segmentation: Precision Solutions for Different Scenarios

Ultra-Light Daily Use (15–18 lbs / 7–8 kg)

Features: Basic functions streamlined to the extreme, can be lifted with one hand

Applicable scenarios: Active users who frequently transport by car, serving as a second "travel-specific" wheelchair

Typical design: Fixed armrests and footrests, minimal or no backrest, narrow-wheel design

Balanced All-Rounder (18–22 lbs / 8–10 kg)

Features: Optimal balance between weight and functionality

Applicable scenarios: Primary daily wheelchair, balancing home use and portability for outings

Retained functions: Adjustable footrests, detachable armrests, moderate seating system

Adjustable Growth Type (22–25 lbs / 10–11 kg)

Features: Maintains lightweight while offering multiple adjustment options

Applicable groups: Growing children, users requiring precise posture management

Unique value: Multi-dimensional adjustability (seat width, depth, backrest angle, etc.)

Sports-Oriented (Special Lightweight Design)

Features: Optimized for sports like basketball and tennis, wheelchair lightweight transport emphasizing maneuverability over extreme lightness

Weight distribution: Meticulously designed center of gravity for quick starts and turns

Durability priority: Special reinforcement to withstand high-intensity use and impacts

Folding Mechanisms: Core Innovation for Portability

Lateral Folding System

Classic design: Folds inward from both sides for the most compact size

Ease of operation: Typically completed in 3–5 seconds with one hand

Modern improvements: Magnetic or snap-fit fixation to avoid loose shaking

Longitudinal Folding System

Space optimization: Neater shape when folded, suitable for storage in specific spaces

Structural advantage: Main frame remains intact for better long-term durability

Usage scenario: Users prioritizing tidy storage in car trunks

Hybrid Folding System

Innovative design: Folds longitudinally first, then laterally for ultimate compactness

Typical outcome: Can fit into a dedicated backpack or small storage cabinet

High-end option: Usually combined with advanced materials like carbon fiber

In-Depth Optimization for Transportation Scenarios

Car Compatibility Design

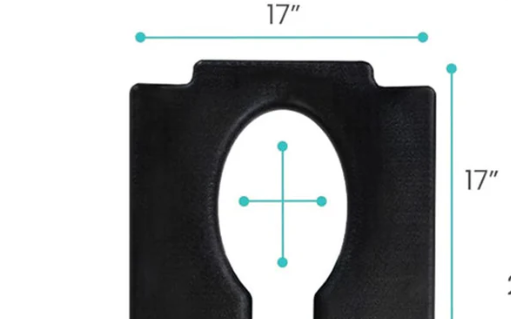

Folded size standards: Targeted to fit into compact car trunks

Anti-roller stain design: Special wheel covers to prevent soiling car interiors

Quick fixation solutions: Simple seatbelt systems to prevent movement during travel

Public Transportation-Friendly Features

Narrow space maneuverability: Flexible movement in bus aisles and subway cars

Anti-pinch design: Prevents accidental pinching of folding mechanisms in crowded environments

Self-standing capability: Can stand stably when folded without leaning

Air Travel Adaptation

Compliance with IATA standards: Size and weight meet major airline regulations

Easy identification marks: Prominent "medical device" labels to reduce security check misunderstandings

Critical component protection: Design to safeguard fragile parts when folded

Purchasing Decision Framework

Personal Needs Assessment Checklist

Transport frequency: Multiple times a day or occasional use?

Primary transporter: User themselves, family members, or public transportation staff?

Transport tool limitations: Car model, public transportation type, home storage space

Usage environment mix: Ratio of home use vs. outdoor use

Changes in physical ability: Consider potential changes in the next few years

Key Tests for Trial Use and Transportation

Real handling experience: Simulate the entire process from home to car

Smoothness of folding operation: Whether it remains easy to operate when fatigued

Stability during transportation: Whether it generates noise or moves in the car trunk

Reliability of quick deployment: Ability to prepare quickly in emergencies

Maintenance and Lifespan Management

Special Maintenance Needs for Lightweight Design

Lightweight materials often require more careful maintenance:

Regular torque checks: Lightweight connectors may need more frequent tightening

Cleaner restrictions: Avoid certain chemical cleaners that damage special coatings or materials

Storage environment requirements: wheelchair lightweight transport Extreme temperatures may affect some composite materials

Lifecycle Cost

Although the initial investment is higher (lightweight wheelchairs are typically 30–100% more expensive than standard models), comprehensive considerations show:

Reduced medical costs from transport-related injuries

Intangible value of protecting caregivers’ health

Longer equipment replacement cycles (high-quality lightweight products are more durable)

Higher residual value in the secondary market

Future Outlook: Intelligent Lightweighting

Technology Integration Trends

Integrated sensors: Monitor usage patterns to optimize personalized settings

Smart material applications: Shape-memory alloys for automatic adaptive adjustment

IoT connectivity: Sync with smartphones to provide maintenance reminders and usage data

Energy recovery systems: Convert pushing kinetic energy into device charging power

Sustainability Innovations

Biocomposites: Bio-based materials reinforced with flax or bamboo fiber

Modular upgrades: Allow replacement of partial components instead of full device updates

Global recycling standards: Establish cross-brand material recycling and regeneration systems

Social Impact: Transformation Beyond Equipment

The popularization of lightweight transport wheelchairs is triggering a series of positive social changes:

Shift in Spatial Concepts

Public places are beginning to provide storage spaces tailored to lightweight wheelchair sizes

Car design incorporates more wheelchair-friendly transportation solutions

Housing design integrates intelligent storage for wheelchairs

Increased Social Participation

When transportation is no longer a major barrier:

Participation rates in spontaneous social activities rise

Commuting range for employment expands

Willingness to travel and explore increases significantly

Psychological Liberation Effect

The most profound changes brought by lightweight design are often psychological:

Reconstruction of the sense of autonomy: "I can handle this myself"

Enhanced dignity from reduced reliance on others

Increased initiative and confidence in participating in activities spontaneously

Conclusion: Reduced Weight, Multiplied Possibilities

Choosing a lightweight transport wheelchair is essentially choosing a more free and autonomous lifestyle. Every gram of weight reduced means an easier handling experience, a more spontaneous trip, and a more equal participation opportunity.

Behind this seemingly simple technological improvement lies the profound attention of human engineering wisdom to quality of life: we not only help people move, but help them move easily; wheelchair lightweight transport we not only provide transportation tools, but also the joy of transportation; we not only solve physical barriers, but also liberate psychological burdens.

When a lightweight wheelchair is folded and gently placed in a car trunk or leaned against a wall, it is no longer a conspicuous medical device, but a ready-to-serve life companion—lightweight, low-key, powerful, and always prepared to support the next adventure, the next exploration, and the next connection with the world.

In this chair, reduced weight is transformed into increased possibilities; streamlined structure expands the radius of life; engineering precision creates human freedom. This is the true revolution brought by lightweight transport wheelchairs—not only changing how people move, but how people live.